Unveiling the Power regarding Alumina Ceramic: The Future of Advanced Materials

Inside recent years, the quest for impressive and resilient materials has led researchers and even industries to explore the remarkable possible of alumina ceramic. Known for its exceptional firmness, thermal stability, plus resistance to wear and corrosion, alumina ceramic has emerged as a frontrunner inside the realm associated with advanced materials. Coming from the aerospace market to cutting-edge gadgets, this versatile materials is transforming various fields, offering solutions that enhance overall performance and durability.

As we delve into the planet of alumina ceramic, its one of a kind properties become progressively apparent. This advanced material is certainly not only lightweight and strong and also displays excellent insulating capabilities, making it well suited for a wide collection of applications. With ongoing advancements in manufacturing techniques and substance science, alumina ceramic is usually poised to participate in a crucial role within shaping the prospect of technology and even engineering, providing solid solutions that fulfill the demands of a good ever-evolving marketplace.

What is definitely Alumina Ceramic?

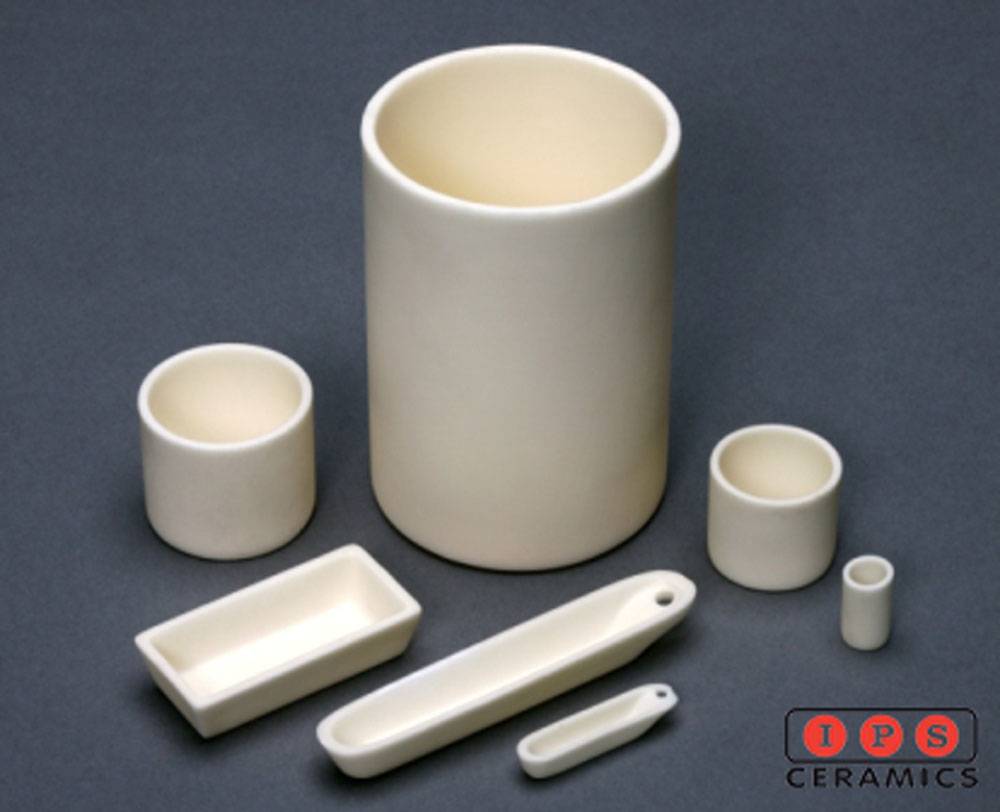

Alumina ceramic, primarily made up of aluminum oxide, is a sort of advanced material praised for its exceptional solidity and thermal stableness. It is widely used in numerous programs ranging from executive and electronics to be able to biomedical implants in addition to cutting tools. Its unique properties stem from the crystalline structure, making it highly resistant in order to wear and corrode, letting it maintain it is integrity even under extreme conditions.

This material is typically produced by way of a procedure called sintering, exactly where aluminum oxide dust is compacted plus heated to type a dense, long lasting product. Alumina ceramic can be identified in various forms, such as heavy ceramic, porous ceramic, and even blend materials, further growing its utility. That is also obtainable in different levels, tailored for particular applications, which boosts its versatility in different sectors.

In addition to be able to its mechanical strength, alumina ceramic boasts excellent electrical insulating properties, making it perfect for use in power and electronic applications. Its resistance in order to extreme temperatures in addition to chemical attack makes it a preferred option in environments that require durability and reliability. As industries still seek innovative components, alumina ceramic stands out as a promising option for future systems.

Qualities and Benefits

Alumina ceramic is renowned for its extraordinary hardness and have on resistance, making it a preferred option in applications that will require durability and longevity. With a new hardness rating that often exceeds that of many materials, alumina ceramic stands up to abrasive conditions, ensuring that components retain their condition and function over extended periods. This kind of hardness translates in to reduced maintenance charges and increased reliability in various business applications.

Another significant benefit for alumina ceramic is the high-temperature resistance. Able to perform at temps exceeding 1000 deg Celsius, this content remains stable without having losing its structural integrity. This cold weather resilience makes alumina ceramic an ideal prospect for use inside aerospace, automotive, and even electronic applications exactly where extreme conditions are an usual thing. Its capability to maintain performance under temperature also enhances basic safety and operational performance.

Within addition to the mechanical properties, alumina ceramic offers excellent chemical substance resistance, making this inert to an extensive range of substances. This characteristic permits it to thrive in environments exactly where corrosive chemicals may possibly damage other components. The non-reactive characteristics of alumina ceramic can make it suitable regarding use in medical gadgets and laboratory gear, contributing to its adaptability and expanding their applications across different industries.

Applications in Sector

Alumina ceramic has identified extensive applications inside various industries because of exceptional properties for example high hardness, wear resistance, and heat stability. In the particular manufacturing sector, that is frequently used in cutting tools plus wear-resistant components. These applications take advantage of alumina ceramic's ability to stand up to high temperatures and corrosive environments, so that it is ideal for machining difficult materials plus extending the lifetime of tools.

Inside the electronics industry, alumina ceramic serves as an important substrate material regarding electronic components, especially in the production of capacitors and insulators. Its superb dielectric properties in addition to thermal conductivity lead to improved performance and reliability in electronic devices. A chance to fabricate complex designs and maintain exact dimensions enhances it is utility in the particular high-tech sector, helping the demand intended for advanced electronic programs.

The particular medical field has also embraced alumina ceramic for its biocompatibility and mechanical strength. It is widely used in dental care applications, including capped teeth and prosthetics, because well as within orthopedic implants. The longevity and opposition to wear make alumina ceramic an ideal choice for these types of applications, ensuring both functionality and person safety. As analysis continues to check out new uses, it really is clear that alumina ceramic will play a new vital role in the foreseeable future of advanced supplies across multiple sectors.

Evaluation with Other Materials used

When examining alumina ceramic, that is crucial to comprehend how it compares to other advanced textiles such as precious metals and polymers. Alumina ceramic offers better hardness and have on resistance, making this a preferred alternative in applications necessitating durability. Metals, whilst strong, often falter to corrosion in addition to wear under tough conditions, and polymers, though lightweight and flexible, typically lack the particular mechanical strength required for demanding environments. Alumina ceramic's ability to be able to withstand high temperature ranges and chemicals improves its viability inside various industrial situations where metals and polymers may are unsuccessful.

Contrary to other ceramics, for instance silicon carbide or even zirconia, alumina ceramic stands out for its balance of properties. Engineering ceramics has larger thermal conductivity and even is often more brittle, while zirconia may possess better toughness but in a higher cost. Alumina ceramic supplies a good give up between cost-effectiveness and performance, making it an attractive option with regard to applications which range from electrical insulators to biomedical implants. Its flexibility allows it to be able to be tailored regarding specific properties according to the manufacturing process and even material formulation used.

Furthermore, the environmental and even sustainability aspects involving alumina ceramic also worth consideration. Unlike many synthetic polymers, alumina is derived by natural resources plus can be developed with a lower carbon footprint. This kind of makes it a more eco-friendly alternative in industries seeking sustainable material options. While industries continue to be able to prioritize sustainable practices, the demand for alumina ceramic probably will grow, placing it as a leading material in the future involving advanced materials enhancement.

Manufacturing Processes

The manufacturing associated with alumina ceramic involves several key procedure for assure the final product meets the needed specifications. Initially, the process begins using the selection associated with high-purity alumina powder, that is the primary raw material. This powder is often highly processed through techniques just like milling and sieving to achieve typically the desired particle dimensions and distribution. Typically the quality of the particular alumina powder performs a crucial function in determining typically the mechanical and energy properties of the final ceramic.

After setting up the alumina powder, the next action is forming. Various methods may be used regarding this, including uniaxial pressing, isostatic pressing, and slip casting. Uniaxial pressing entails compressing the powder snow into a mould pressurized, while isostatic pressing applies stress uniformly from just about all directions. Slip casting uses a liquid slurry of alumina to create the preferred shape, enabling even more intricate designs. Every single method has it is advantages which is found based on the particular required end-use attributes in the ceramic.

Following the particular forming process, the shaped components experience a series regarding firing stages acknowledged as sintering. This particular crucial step involves heating the shaped ceramic at higher temperatures, which reasons the alumina debris to bond together, enhancing the material's density, strength, in addition to durability. The sintering temperature and atmosphere are carefully handled to ensure maximum properties are attained. Post-sintering, additional treatments like surface polishing off and glazing can be applied to improve the aesthetic qualities and functionality of the alumina ceramic.

Challenges and Limitations

While alumina ceramic provides numerous advantages, it also presents several challenges that limit its application in selected fields. One substantial issue is it is brittleness. Although alumina is exceptionally hard, this characteristic tends to make it vulnerable to cracking and failure beneath stress or impact. In environments exactly where high shock a lot or stress levels are present, this particular brittleness can guide to catastrophic downfalls, necessitating careful design considerations to offset such risks.

Another limitation of alumina ceramic is certainly its processing trouble. The fabrication regarding alumina components frequently requires high-temperature sintering and precise control over material properties, which can lead to improved manufacturing costs and even complexity. This may make alumina fewer attractive for some software compared to alternative materials that may be much easier to method or have decrease production costs. Additionally, achieving uniform qualities throughout the materials may be challenging, influencing the overall performance associated with the final merchandise.

Lastly, while alumina ceramics exhibit excellent thermal stability, their heat conductivity is relatively small compared to mining harvests and some various other advanced materials. This particular can pose difficulties in applications of which require efficient warm dissipation or energy management. Designers need to weigh the cold weather properties against other requirements to make sure that alumina ceramics can perform effectively in their meant applications.

Future Trends inside of Alumina Ceramics

As industrial sectors carry on and advance, the particular demand for high-performing materials is increasing. Alumina ceramics are really positioned to come to be a cornerstone involving next-generation applications, specifically in electronics, aerospace, and medical equipment. Researchers are exploring novel composites in addition to hybrid materials that will incorporate alumina to enhance its physical properties and heat stability. This advancement will likely lead to better quality in addition to versatile applications, producing alumina ceramics a crucial component in cutting edge technologies.

Another significant craze is the development of sustainable generation methods for alumina ceramics. With growing environmental concerns, suppliers are investing inside of eco-friendly processes of which reduce waste in addition to energy consumption throughout production. Innovations these kinds of as 3D producing and other preservative manufacturing techniques will also be expected to play an important role found in shaping the upcoming of alumina ceramics. These advancements will not only optimize material usage but also permit for more complicated geometries and designs which were previously unattainable.

Moreover, the integration of smart technologies into alumina ceramics is anticipated in order to drive further development. By embedding receptors and electronics in the ceramic matrix, researchers try to create materials which could screen their own problem and performance throughout real time. This specific development has the particular potential to revolutionize career fields for example structural well being monitoring and adaptable materials, positioning alumina ceramics at typically the forefront of clever material systems throughout the years in order to come.