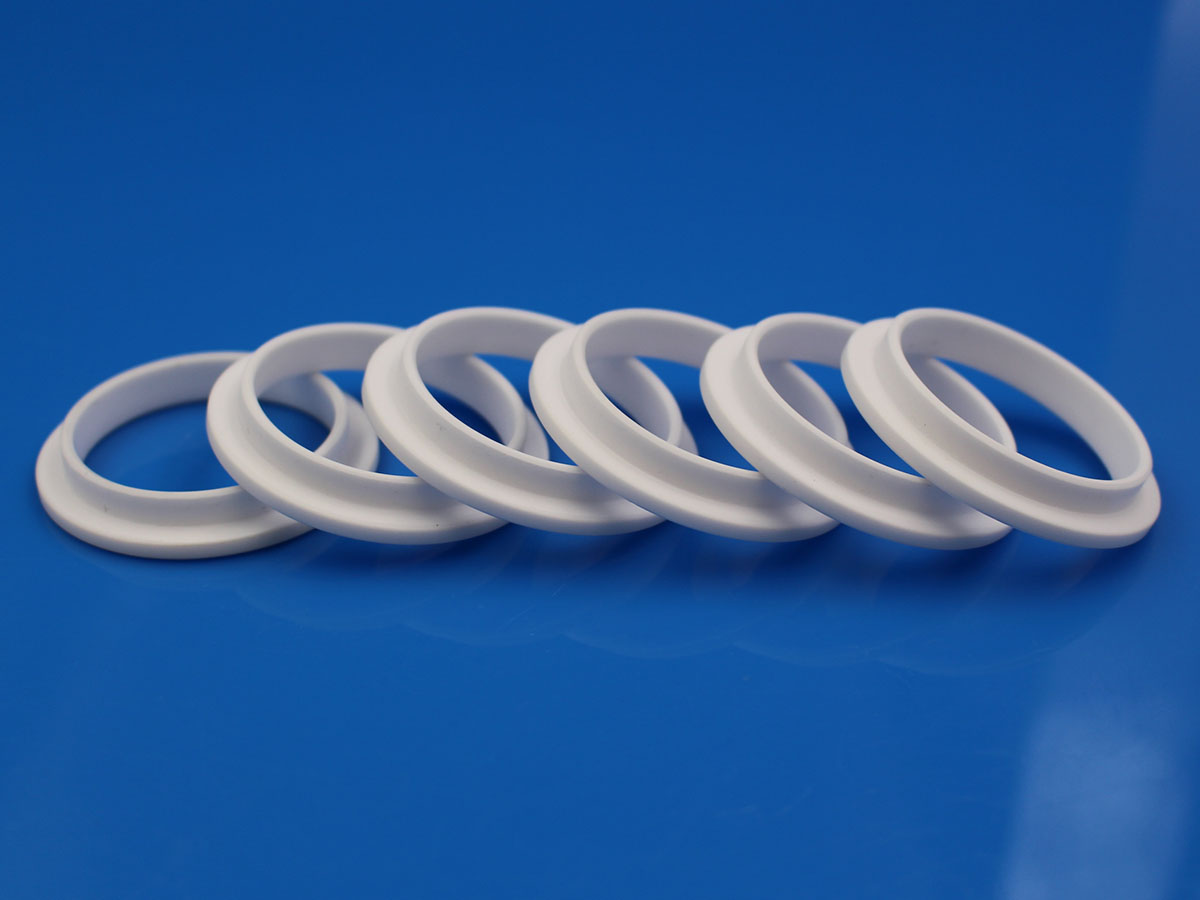

Unveiling the Power of Alumina Ceramic: The particular Future of Superior Materials

Throughout recent years, there have been a remarkable switch within the materials technology landscape, with alumina ceramic emerging as some sort of frontrunner in superior materials for various applications. This adaptable substance, praised for their incredible hardness, thermal stability, and level of resistance to wear, is usually finding its way into industries ranging from electronics to aeronautical. As we keep on to seek supplies that can withstand extreme conditions while maintaining performance, alumina ceramic sticks out as a strong solution.

The unique properties of alumina ceramic make that not only the practical choice nevertheless also a sustainable one. Having the ability to end up being engineered for specific applications, this material adds to innovations of which help reduce fat, increase efficiency, and enhance durability. As we look into the world of alumina ceramic, you will explore its benefits, diverse applications, plus the promising future it keeps for several sectors looking to be able to elevate their functionality through advanced materials.

Exactly what is Alumina Hard?

Alumina ceramic is a kind of advanced ceramic materials that consists largely of aluminum oxide, or alumina. This compound is known for its amazing mechanical properties, that include high hardness, outstanding wear resistance, and even outstanding thermal stability. Because of these qualities, alumina ceramics are traditionally used in various applications starting from industrial components to biomedical devices.

One regarding the key qualities of alumina ceramic is its ability in order to withstand extreme temperatures without significant degradation. Its chemical stableness further helps it be the popular choice inside of environments that involve experience of corrosive materials. The material can end up being engineered to have differing degrees of porosity and grain sizes, enhancing its adaptability for specific utilizes, such as within cutting tools, protecting materials, and electrical components.

Researchers are constantly exploring new formulations and processing approaches for alumina ceramic to enhance its performance and even expand its prospective applications. Innovations in manufacturing processes, such while additive manufacturing, are usually paving the way for customized designs that leverage the unique properties of alumina, setting typically the stage for their increasing importance inside of future material research developments.

Properties of Alumina Ceramic

Alumina ceramic is renowned for it is remarkable hardness in addition to wear resistance, making it a highly regarded alternative for applications demanding durability. Which has a Mohs hardness rating of approximately 9, it is second only to diamond. This outstanding hardness allows alumina ceramics to tolerate significant mechanical stress while maintaining their particular structural integrity. Therefore, they are extensively applied to cutting tools, wear parts, in addition to protective coatings in which abrasion and influence resistance are important.

In addition to their hardness, alumina ceramic displays excellent thermal steadiness and resistance in order to high temperatures. It can maintain its components up to 1700 certifications Celsius, making it ideal for use in high-temperature environments. This kind of thermal resilience will be complemented by it is low thermal conductivity, which helps to minimize heat transfer, thus protecting delicate components in electric and mechanical applications. Furthermore, alumina ceramics have a very low pourcentage of thermal development, ensuring dimensional stability across a line of temperatures.

The electric powered insulation properties of alumina ceramic further enhance its appeal in various industries. With the high dielectric power, it serves like an effective insulator, preventing the flow of electric existing in electronic parts and devices. This property is vital for applications inside the electronics sector, where insulation is necessary to ensure safety and performance. Combined with its chemical resistance, alumina ceramic becomes an exceptional material choice intended for environments confronted with tough chemicals and corrosive substances.

Applications in Market

Alumina ceramic is progressively recognized for their versatility across several industrial applications. 1 of the almost all significant uses associated with alumina ceramic is found in the field involving electronics. Its outstanding insulating properties plus high thermal balance make it a good ideal material for substrates in digital circuits, capacitors, plus insulators. Additionally, the particular ability to tolerate great heat without uncomfortable helps to ensure that alumina ceramic pieces can function effectively in demanding environments, surrounding to the stability of electronics.

Within the vehicle industry, alumina ceramic offers carved a niche due to the wear opposition and durability. It will be utilized in components such as ignite plugs and powerplant parts, where that not only increases performance but in addition expands the lifespan regarding these critical pieces. The lightweight mother nature of alumina ceramic likewise contributes to increased fuel efficiency, building it a well-liked alternative in the pursuit of sustainable automotive solutions.

Another prominent application associated with alumina ceramic is inside the biomedical line of business. Its biocompatibility allows for its use on implants and prosthetic devices, helping in order to foster integration using human tissue. Moreover, its hardness and resistance to use make alumina ceramic an excellent option for oral applications, including caps and bridges. Since the with regard to innovative materials grows, alumina ceramic is poised in order to play a crucial role in the ongoing innovation within just these industries.

Advantages More than Other Materials

Alumina hard stands out amongst various materials because of to its exceptional hardness and use resistance. These properties make it ideal for applications that require durability and even longevity, such like in cutting resources, industrial machinery, and wear-resistant coatings. Unlike metals, which can deform and use over time, alumina maintains its strength integrity even beneath harsh conditions, ensuring reliability in challenging environments.

Another significant advantage of alumina ceramic is it is excellent thermal stableness. It can withstand great heat without deforming or degrading, producing it suited to make use of in heat-intensive programs like kilns and furnaces. Additionally, it is low thermal conductivity is beneficial on applications where insulating material is important, providing strength efficiency and protection against heat loss.

Alumina ceramic is additionally very resistant to chemical corrosion, which is definitely a common concern for many supplies when exposed to chemicals or environment conditions. This real estate allows it to be able to be applied to adjustments that involve reactive substances without the threat of degradation. As a result, alumina ceramic offers a new robust and flexible solution in several companies, setting it apart from traditional materials that may not really provide such a new comprehensive array of positive aspects.

Producing Processes

The manufacturing involving alumina ceramic involves various key processes of which ensure the introduction of premium quality materials well suited for numerous applications. Initially, the raw materials, mainly alumina powder, go through thorough mixing and blending to achieve uniformity. This phase is crucial as it directly affects the particular properties of typically the final product. Other additives may in addition be included to enhance specific characteristics enjoy strength and cold weather stability.

Once the natural material mix is usually prepared, the subsequent phase is shaping. Various techniques for example uniaxial pressing, isostatic pressing, and slide casting can end up being employed to create typically the desired shapes. Alumina ceramics in industry has it is advantages, depending about the complexity and even size of the particular component being created. After shaping, typically the green bodies produced from the natural mix are subjected to a drying procedure, which removes excess moisture, preparing these people for the future firing stage.

The last step in the particular manufacturing process is usually sintering, where the shaped green body are heated in high temperatures in a controlled environment. This process causes the contaminants to bond and even densify, resulting in robust alumina ceramics. The sintering temp and time are really critical parameters of which influence the physical and thermal properties from the final item. After sintering, any necessary finishing procedures for example grinding or polishing may become employed to obtain accurate dimensions and area qualities.

Future Trends inside Alumina Porcelain

The ongoing future of alumina ceramic is poised regarding significant advancements, motivated by ongoing exploration and development in materials science. Since industries continue to be able to seek more durable and lightweight materials, alumina ceramic stands out as a result of to its amazing mechanical properties in addition to resistance to use. It is particularly relevant in sectors such as aerospace, vehicle, and biomedical apps. The increasing need for high-performance materials is likely in order to spur innovative supplements and processing strategies that improve the features of alumina ceramic.

Additionally, ecological sustainability is now the critical focus across various industries. Producers are increasingly researching ways to incorporate eco-friendly conditions into the creation of alumina ceramic. This may add the employ of recycled supplies and energy-efficient production methods. The possible for alumina ceramic to be part associated with sustainable solutions illustrates its versatility in addition to reinforces its position at a later date material enhancements. As being the industry leans towards greener procedures, alumina ceramic will probably adapt, making certain it meets both overall performance and environmental requirements.

In addition, integration with smart technologies is expected to play the pivotal role inside the evolution of alumina ceramic. The development regarding smart ceramics, which can respond to be able to environmental stimuli or perhaps self-monitor performance, will be an exciting frontier. By combining alumina with other elements or embedding sensors, future generations associated with alumina ceramics could lead to breakthroughs in numerous applications, including healthcare monitoring devices and advanced manufacturing. This particular intersection of materials science and technological innovation is set to unlock new possibilities with regard to alumina ceramic, making this an integral portion of the superior materials landscape.

Summary

Alumina ceramic stands as being a testament to the developments in materials scientific research, showcasing its adaptability and robust properties. Its remarkable power, high-temperature resistance, in addition to excellent wear qualities position it while a frontrunner inside various industrial programs. The growing require for reliable materials used in sectors for example electronics, aerospace, and biomedical engineering simply highlights the potential of alumina ceramic within shaping the continuing future of modern day technology.

As research and development always push the boundaries involving alumina ceramic, innovations within processing techniques in addition to formulations are expected to be able to enhance its overall performance even further. This particular ongoing progress pledges to unlock brand-new applications and enhance existing ones, strengthening alumina ceramic's place in both traditional and emerging industrial sectors. With its capability to meet the requiring requirements of essential environments, its meaning is merely set to increase.

The future of alumina ceramic is brilliant, driven by their unique properties plus the need for advanced materials. Because industries evolve and even seek sustainable in addition to efficient solutions, alumina ceramic is poised in order to play a pivotal role. Embracing this particular material will not only lead to technological advancements but also foster sustainability inside manufacturing processes, introducing the way for any new era in material science.